China has placed much emphasis on encouraging large-scale equipment renewal and trade-ins of old consumer goods over the past year, with the topic being highlighted both at the Central Economic Conference held at the end of 2023 and in the government work report of 2024.

In March 2024, the State Council released an action plan to promote large-scale equipment upgrading and trade-ins of consumer goods, declaring that by 2027 the investment in equipment used for industry, agriculture, construction, transportation, education, culture, and tourism, and healthcare should increase by more than 25 percent from 2023. This has subsequently driven the launch of a massive campaign.

Industry is pivotal to the national economy. Shortly after the action plan was released, seven departments, including the Ministry of Industry and Information Technology (MIIT), jointly released an implementation plan for promoting equipment upgrading in the industrial sector. According to the plan, which focuses on promoting new industrialization, China will advance high-end, intelligent, and green development of its manufacturing sector.

Operators of YTO’s “Dongfanghong” tractors working as a team in the fields.

Technological Transformation and Industrial Development

Over the past 70 years since the founding of the People’s Republic of China (PRC), China has developed into the world’s largest industrial manufacturer, offering high-quality products. In this process, technological transformation has played a key role.

In the 1950s, China introduced 156 key industrial and mining construction projects (collectively referred to as the “156 Projects”) from the Soviet Union and Eastern European countries, which laid the economic foundation for China’s industrialization drive. It was also the first time since the founding of the PRC that state-owned enterprises got the chance to make great strides in technological progress.

China’s largest tractor manufacturer, the First Tractor Manufacturing Factory (the predecessor of YTO Group Corporation), was born against this background. The “Dongfanghong” tractor it developed was the first high-power caterpillar tractor of the PRC, ushering in a new era that saw cattle being replaced in the plowing of fields.

Yu Lina, a member of the Standing Committee of the YTO Group Corporation CPC Committee and deputy general manager of the company, said that caterpillar tractors have been YTO’s flagship products for about 30 years. Later, in the early 1980s, when the country promoted a new round of product upgrades, YTO introduced advanced wheeled tractors into China, laying the foundation for domestic production of such tractors.

“At that time, China had a weak industrial foundation, and there was a lack of supporting facilities for the equipment and parts required to produce wheeled tractors,” said Yu. According to her, after introducing foreign products, YTO continued to hone its capabilities by digesting and absorbing advanced technology. After 20 years, YTO had not only completed the full localization of wheeled tractors, but also grown into a large-scale agricultural machinery and equipment manufacturer with a complete industrial system. In recent years, through independent R&D and technical cooperation, it has continued to develop and become a household name in the industry.

Over the past few decades, after several rounds of technological transformation and upgrading, YTO’s “Dongfanghong” tractors and after-sales service outlets have covered almost the entire country, contributing significantly to China’s agricultural mechanization. Meanwhile, the products are also sold to more than 100 countries and regions including Russian-speaking areas, Southeast Asia, Central and Eastern Europe, and Africa. Its brand influence continues to expand.

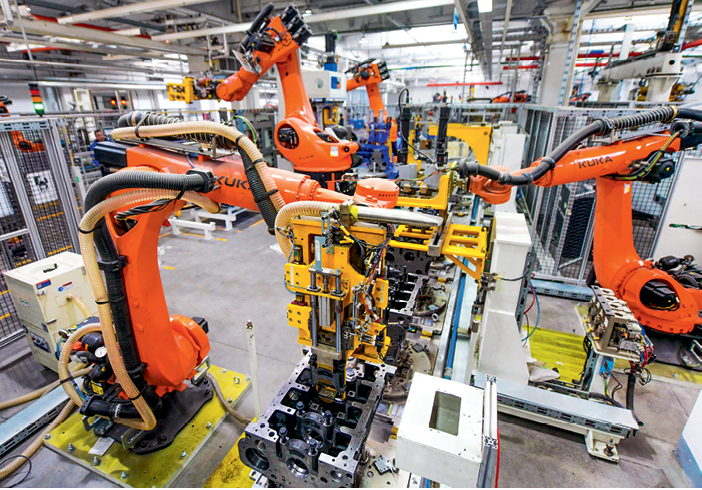

In YTO’s YTN new platform diesel engine workshop, machines, equipment, and orange robotic arms operate in an orderly manner, with a distinct absence of human workers.

New Opportunities

Chen Bin, a member of the Standing Committee of the CPC Committee and deputy director of the Expert Committee of the China Machinery Industry Federation (CMIF), has worked in state agencies for years and has rich management experience. According to Chen, each of China’s Five-Year Plans attaches great importance to technological transformation, and at different periods China has different priorities for this task. This year is not the first time that large-scale technological transformation has been implemented.

In December 2008, in response to the global financial crisis, the Central Economic Work Conference set the goals of “maintaining growth, expanding domestic demand, and adjusting structure.”

“At that time, China urgently issued 10 major industrial adjustment and revitalization plans, pointing out the direction for large-scale technological transformation,” said Chen. The technological transformation actions implemented nationwide fared well, reversing the downward trend of industrial growth in a short period of time, and laying the foundation for structural adjustment, transformation, and upgrading of various industries, said Chen. He took the automobile industry as an example. In 2008, automobile production and sales were more than nine million units. The figure doubled in just two years, exceeding 18 million units and rising to be among the largest in the world.

In the fourth quarter of 2021, at a symposium on the state of the economy held by several national departments, CMIF proposed implementing large-scale green and low-carbon transformation in the manufacturing industry. “The investment willingness of domestic enterprises was low, but a large amount of industrial equipment in China needed to be renewed. Furthermore, China has proposed to achieve carbon peaking in 2030. If enterprises want to keep developing, it is imperative to renew their equipment and implement large-scale green and low-carbon technological transformation,” said Chen.

Different from the goals set in 2008, “the current action focuses on green, low-carbon, and digital transformation, which can not only expand domestic demand and drive corporate investment, but also lay the foundation for digital transformation and the realization of the dual carbon goals,” said Chen.

“There is potential demand in the market, but investors are sitting on the fence,” said Chen. He believes that once the country takes action with a clear direction and priorities, and the whole country is mobilized from top to bottom, the triple pressures of shrinking demand, supply shocks, and weakening expectations faced by China’s economy will be alleviated significantly.

Towards the Dual Carbon Goals

At the end of May 2024, the State Council issued the 2024-25 action plan for energy conservation and carbon reduction, aiming to save energy equivalent to 50 million metric tons of standard coal and reduce about 130 million metric tons of carbon dioxide emissions. It also put forward specific requirements for promoting energy-saving and carbon-reducing technological transformations for the steel, petrochemical, non-ferrous metals and other industries.

In order to achieve green, low-carbon and sustainable development and meet the country’s ever-increasing environmental protection requirements, in recent years YTO has developed YTN new platform diesel engine products based on its years of technological achievements in the field of non-road diesel engines. These products not only meet the National IV emission standards, but also have large power per liter, light weight, low fuel consumption, and high adaptability. At the same time, the company is making technical preparations for a shift to the national V emission standard.

In YTO’s YTN new platform diesel engine workshop, machines, equipment, and robotic arms operate in an orderly manner, with a distinct absence of workers. Yu introduced that this production line adopts an unattended factory model, basically realizing unmanned production throughout the entire process. The automation rate of the assembly line can reach 65 percent, forming an intelligent manufacturing production base with an annual output of 50,000 YTN diesel engines, with the ability to expand to 100,000.

The technological transformation and equipment renewal of YTO reflects that of China’s agricultural machinery industry as a whole. The new diesel engine intelligent manufacturing line is also a prime example of building intelligent manufacturing factories in China’s agricultural machinery industry.

In recent years, despite market headwinds at home and abroad, YTO’s performance has continued to hit record highs. Yu believes that one of the important reasons is YTO’s insistence on equipment upgrading and technological transformation. She hoped that more old equipment and basic pipe networks could be renewed to further reduce energy consumption and improve production efficiency.

The production line of YTO’s YTN new platform diesel engine adopts an unattended factory model, basically realizing unmanned production throughout the entire process.

A Good Start

With the advent of new equipment, it begs the question, what happens to the old equipment? This remains unsettled, even for YTO. For the time being, Yu said, “Usually, some old equipment that is still usable will go to the second-hand equipment trading market or public property rights exchanges, and those that cannot be used again will be scrapped. But if the replacement is on a large scale, there is certainly a lot of pressure on enterprises.” Yu hopes that there will be more policy support in this regard in the near future.

On June 18, 2024, Li Chao, deputy director of the Policy Research Office of the National Development and Reform Commission (NDRC), revealed at a press conference that the NDRC arranged investment within the central budget to support key projects for equipment renewal, energy conservation and carbon reduction. The Ministry of Finance has also allocated RMB 500 million to support the scrapping of old agricultural machinery. Meanwhile, the People’s Bank of China, together with relevant departments, has implemented a re-loan policy for technological innovation.

In addition, the formulation of standards is accelerating. All the 129 national standards to be formulated and revised this year have been approved. Standards in areas such as energy conservation and carbon reduction, environmental protection, and recycling are being further improved.

Currently, four action plans have been issued in seven major areas, including equipment renewal, consumer goods trade-in, recycling, and standard improvement. Thirty-one provinces, autonomous regions, and municipalities have issued implementation plans respectively.

“With the joint efforts of all parties, we have made a good start in promoting large-scale equipment renewal and old consumer goods trade-ins,” said Li.

“From January to May this year, investment in the purchase of equipment and tools increased by 17.5 percent year-on-year, contributing to more than half of all investment growth,” said Li. In the next phase, the NDRC will give leverage to the role of the inter-ministerial joint meeting system, further strengthen overall coordination, increase policy support together with relevant departments, and speed up the allocation of various funds. At the same time, it will provide stronger support, solve relevant problems in a timely manner, and encourage the participation of enterprises and all sectors of society, in a bid to promote large-scale equipment upgrading and old consumer goods trade-ins.