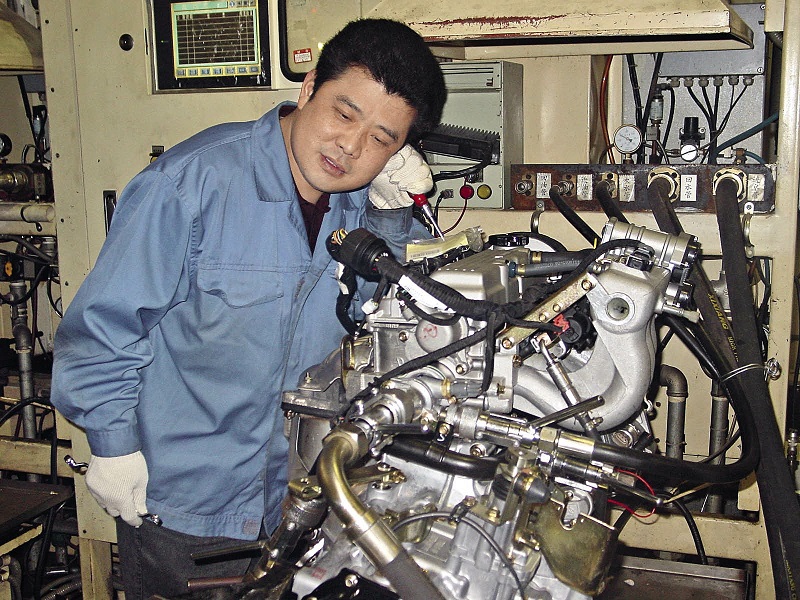

In an engine tuning facility at Chongqing Changan Automobile Co., Ltd., Zhang Yongzhong takes his apprentices through an exercise to spot check a batch of engines. With his years of experience, he notices an imperceptible misfire in one of the engines that signals a problem.

“Wait! The sound of this engine is different from the others!” says Zhang, showing why he’s such an invaluable employee.

Zhang has had an impressive career. He joined the Communist Party of China (CPC) in 2007, has been engaged in the automobile manufacturing industry for more than three decades, is credited with four national patents, and has developed a standard-setting method of engine maintenance. His name is known to everyone at Changan Automobile.

Zhang is the gatekeeper of Changan Automobile’s engine manufacture quality.

Strict Quality Control

The 57-year-old Zhang was born in Jiangbei District, Chongqing. After graduating from high school in 1981, he joined the army and became a signalman. Shortly afterwards, he returned to Chongqing after being discharged and worked as a carpenter in the then Jiangling Machinery Factory. His job was to make outer shells of table clocks and wall clocks.

Zhang worked diligently and was soon able to compete with his master craftsman in work ability. Table clocks had to be inspected after they were assembled, and only qualified products could go to the market. The outer shells of some clocks made by a master craftsmen occasionally had defects and were handed over to Zhang for repairs. After patient and careful mending, the products were able to pass inspection successfully.

One day the workshop manager told him that he and six other workers were selected by the factory to learn about engines.

Soon they began to figure out what to do by disassembling and assembling the engines, learning by observing their mentors and by trial and error. If there was a problem that could not be solved, the factory manager and workshop director would pitch in to help. Sometimes in order to install an engine, they worked from morning to midnight.

After a lengthy apprenticeship, Zhang and his colleagues became more proficient, which inspired them to learn more.

“Do more, ask more, and think more” is Zhang’s motto, and he believes that a person should love the job they do. The aspect of the job he enjoyed the most was troubleshooting. “Discovering problems, finding out the cause, and solving the problem is my greatest pleasure,” said Zhang.

Practice makes perfect, Zhang invented a set of unique techniques to check engines, specifically, looking at the appearance of the engine; smelling the odor of the automobile’s exhaust; and listening to any abnormal noises the engine makes. These criteria would help him find the exact cause of the problem.

One day, in an engine production workshop, Zhang found that the impact sound of workers striking with tools was slightly different from what he normally heard. He immediately checked the display instruments. It turned out that the strength of the strike was lower than required, which could cause the torque of the connecting rod nut to be too low, which would lead to engine failure. The technicians immediately investigated and resolved the problem, and prevented 1,500 unqualified engines from entering the market.

Zhang’s technique, which can quickly and accurately find and solve engine faults, has proved highly practical and is well respected. Proof of this is that it has been promoted in the automobile industry across the country.

Zhang mentors young employees, sharing his technology skills with as many as possible.

Overcoming Bottlenecks

In addition to his unique technique, Zhang is also an inventor who develops tools according to the actual work at hand.

Changan Machinery Factory and Jiangling Machinery Factory merged to form Changan Automobile Co., Ltd. in 1994. During a technical workshop, Zhang found that valve adjustment screws of G series engines often had to be scrapped, which hindered valve clearance adjustment and seriously affected production efficiency.

“Workers can produce 300 to 400 engines on the assembly line every day. We cannot confirm whether the motor is qualified until workers have completed the valve clearance adjustment,” said Zhang. On each engine 16 valve clearances need to be adjusted. If one is not adjusted properly, the whole engine needs to be reinstalled, which is time-consuming and labor-intensive.

Since the production line was imported from abroad, Zhang asked the foreign manufacturer if the tools to adjust the valve clearance needed to be improved, as they were damaging the screws and required constant repair.

With no acceptable resolution from abroad, Zhang took it upon himself to solve this problem. He designed and experimented with his own tools, motivated by the desire to remove this bottleneck from the production line. After the new tool was put into use, the assembly qualification rate was 100 percent and the scrap rate of adjustment screws was zero. The tool he developed not only improved production efficiency, but also obtained a national patent. On the first floor of his workshop, various tools, including torque wrenches are on display, several of which have obtained national patents.

Decades of hard work have taken a large toll on Zhang’s health. Since 2005 he has suffered with pain in his feet, but he ignored the pain and said nothing to his family and colleagues. However, one day in 2006, the pain intensified to the point that he could not bear it. Years of overwork had resulted in femoral head necrosis of both feet, requiring hospitalization and surgical intervention. Even in his hospital bed Zhang used his smartphone to provide remote technical consultations to his colleagues. After his operation, as soon as he was able to move, Zhang walked awkwardly back to the factory with a cane, and returned to his post.

Passing Down Skills

Zhang has worked in motor industry for 39 years, and is set to retire in a few years. What he wants to do most now is to pass on his experience and skills to young employees. To this end, Zhang has signed mentoring agreements with dozens of young employees, committing to pass down his own technology skills to as many as possible, living by the motto,

“The value of a person’s life is to do one’s best to achieve the ultimate in ordinary work.”

At present, more than 80 percent of Changan Automobile’s engine adjusting technicians has received his guidance.

In addition to the technicians at the company headquarters, employees in the company’s maintenance outlets across the country also consult him for advice when they encounter difficult problems, which he is always happy to do.

Changan Automobile is proud to have its very own instruction manual, in which Zhang and his colleagues have compiled their years of engineering experience. The 152 cases in the manual provide answers to many types of common engine failures and has become valuable training material for engine troubleshooting.

Zhang explains his thoughts on work to apprentices, “As long as our work and career are in order, we must go on bravely and not be afraid of difficulties. As with anything in life, as long as you persevere, your efforts will bear fruits.”